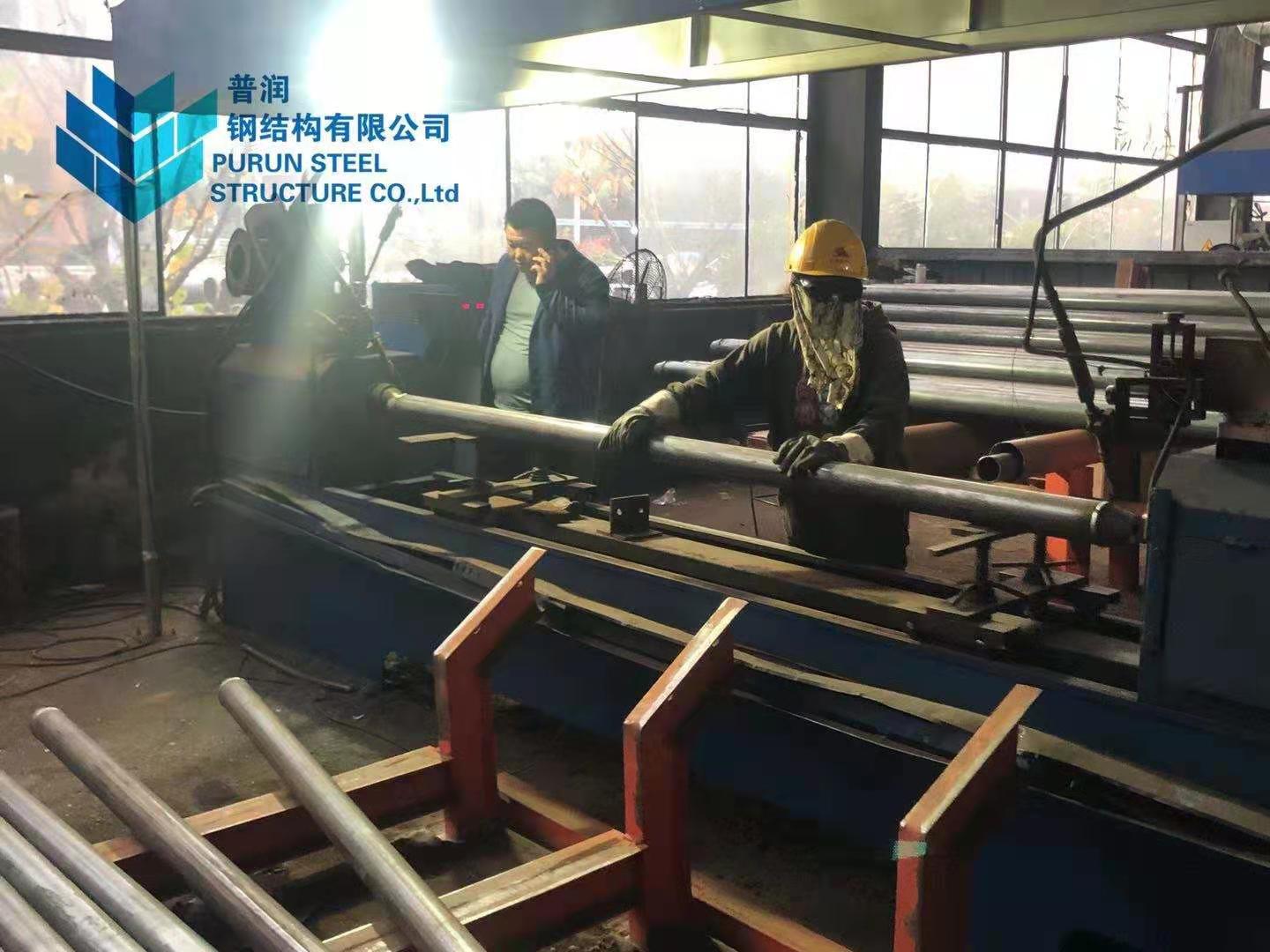

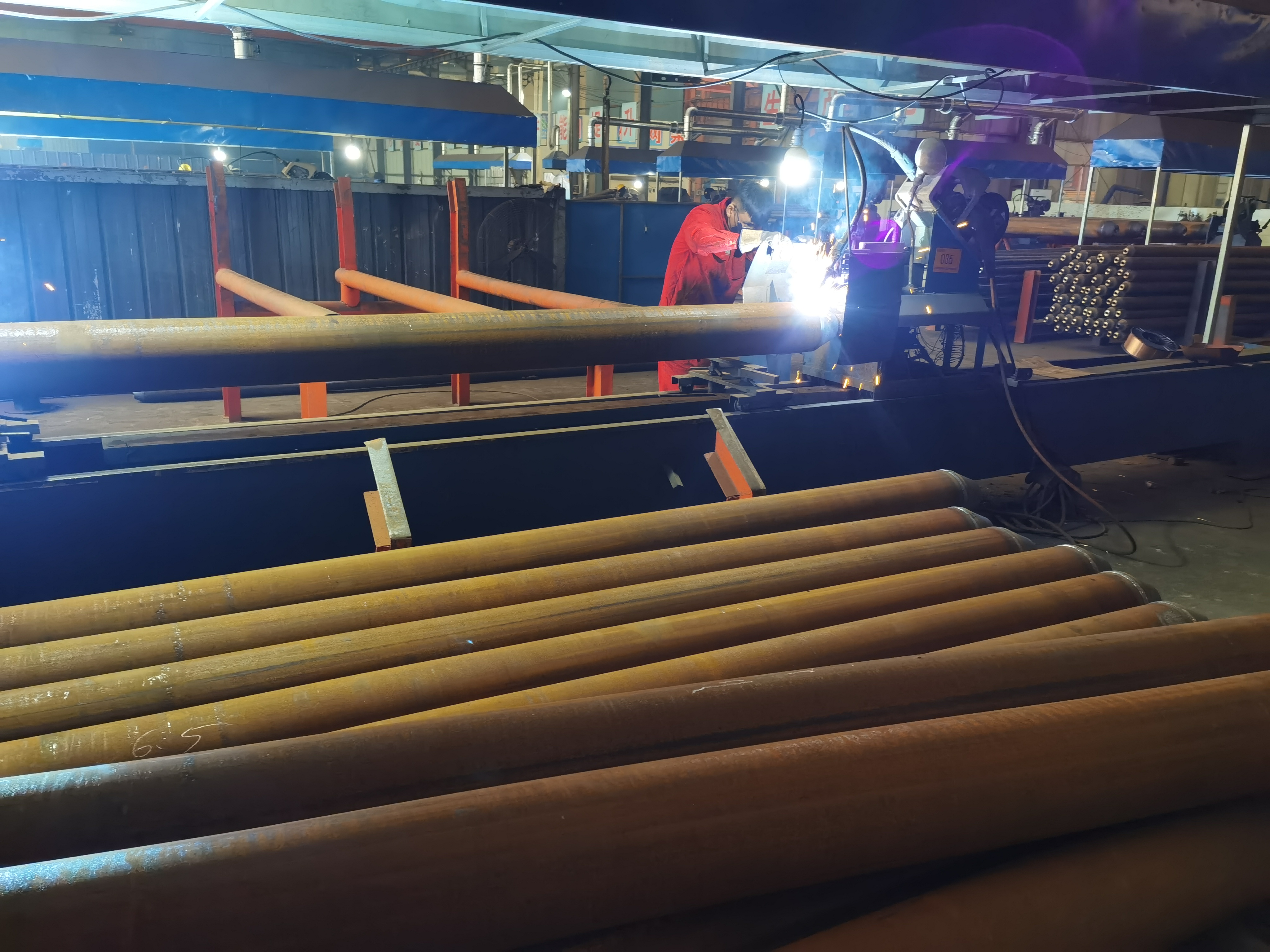

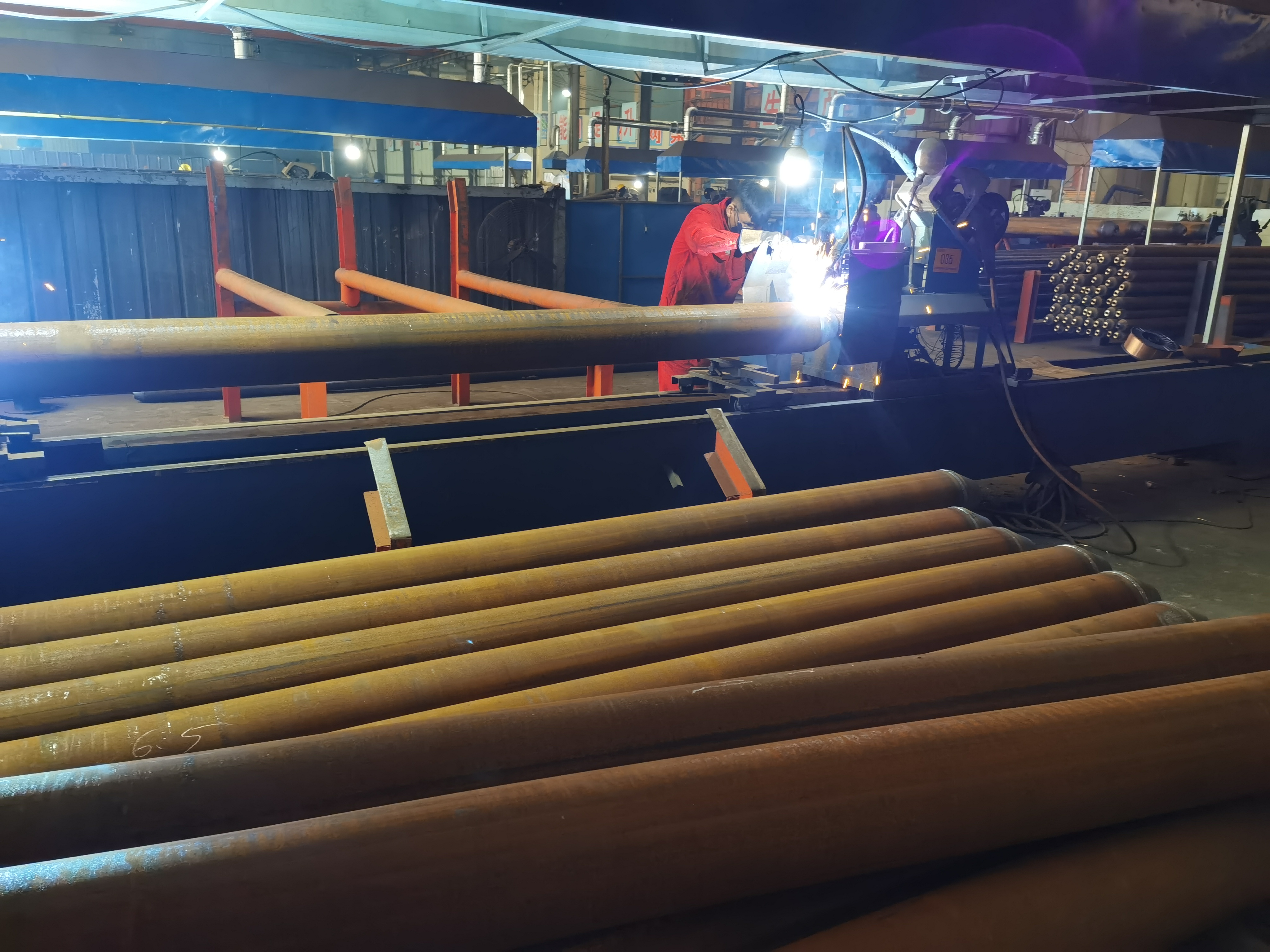

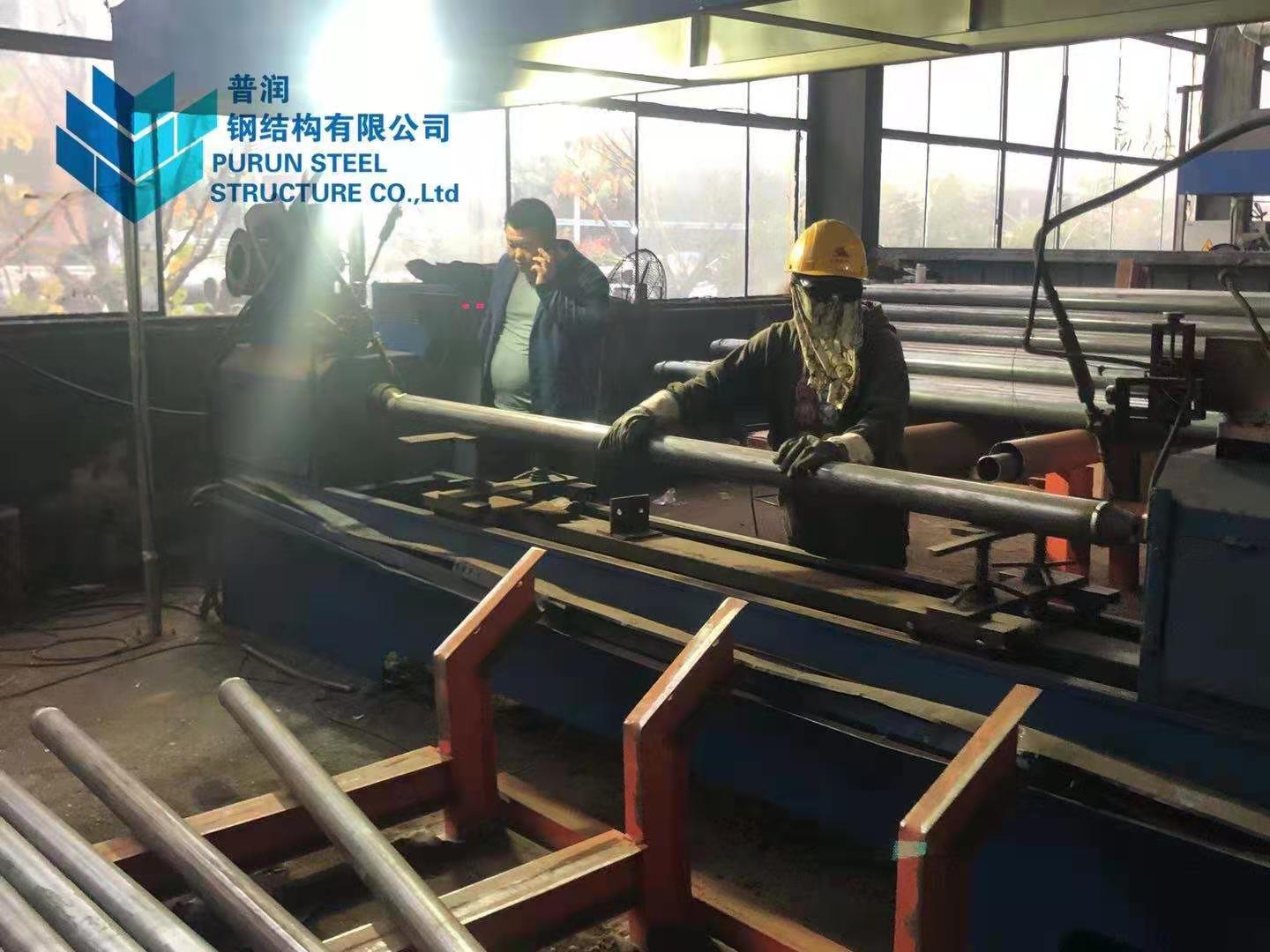

Welding hanya na karfe sarari frame

waldi:

Tsarin waldawa shine muhimmin tsari a cikin samar da firam ɗin sararin ƙarfe, kuma dole ne a aiwatar da shi daidai da umarnin aikin walda.Rage ragowar damuwa da walda ke haifarwa, kuma a gyara nakasar akan lokaci ta hanyar dumama harshen wuta.

A. Lokacin da bututun ƙarfe yana welded tare da farantin rufewa da bututun ƙarfe, za a buɗe tsagi bisa ga buƙatun, kuma kusurwar tsagi za ta cika buƙatun kusurwar da aka kafa tsakanin wutar lantarki da farfajiyar tsagi don guje wa unfusion kuma slag hadawa.Bugu da kari, gibin tsagi ya kamata ya zama Babban isa domin baka na lantarki zai iya kaiwa kasan tsagi kuma ya guje wa zurfin shiga tsakani.

B. Ka guji saita kabu ɗin walda zuwa tsakiyar sandar lokacin da bututun ƙarfe ya lalace.

C. Abubuwan da ke buƙatar kulawa a aikin walda:

a.Lokacin waldawar baka na hannu, kewayon isar da saƙo bai kamata ya yi girma da yawa ba, kuma ana amfani da walda mai yawa da yawa.

A yayin aiwatar da aikin, yakamata a cire tsattsauran igiyar walda ko igiyar walda ta interlayer, haɗar slag, oxide, da sauransu.Dabaran niƙa, ana iya amfani da ƙarfe.

Kayan aiki irin su gogayen waya.

b.Irin wannan kabu na walda ya kamata a ci gaba da yin walda kuma a kammala a lokaci guda.

c.Don haɗin haɗin walda daban-daban, bayan an gama waldawar, yakamata a tsaftace ƙwanƙwasa da ƙurar ƙura a saman walda.

Bincika ingancin walda ɗin, kuma dole ne babu baƙin ciki, walda dutsen dutse, ƙaƙƙarfan yanke, busa, rashin haɗuwa, fasa.

da sauran lahani.

d.Bayan welded na butt ɗin yana waldawa, gano lahani na ultrasonic ya kamata a yi bayan sa'o'i 24.