karfe sarari frame blanking tsari

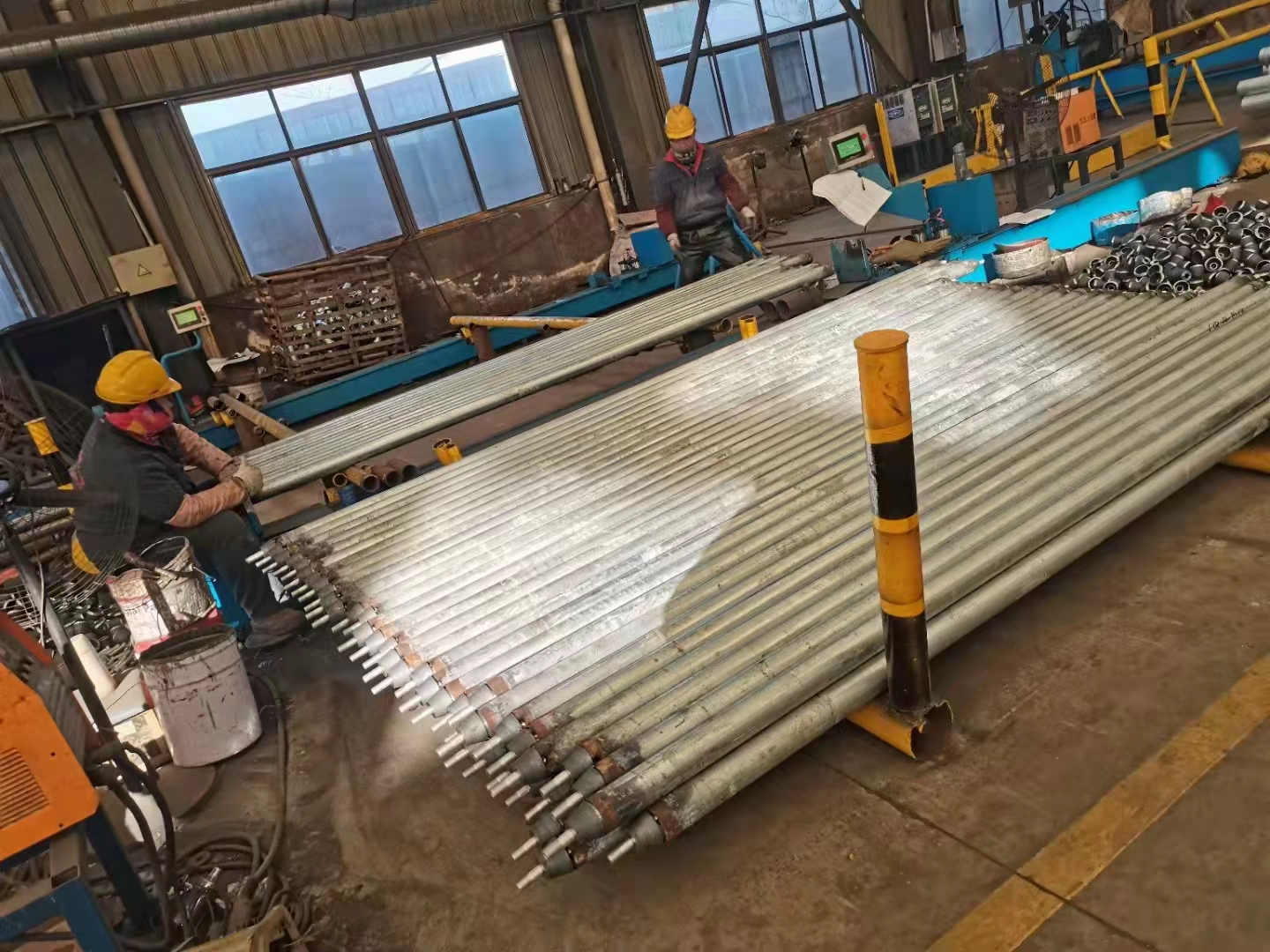

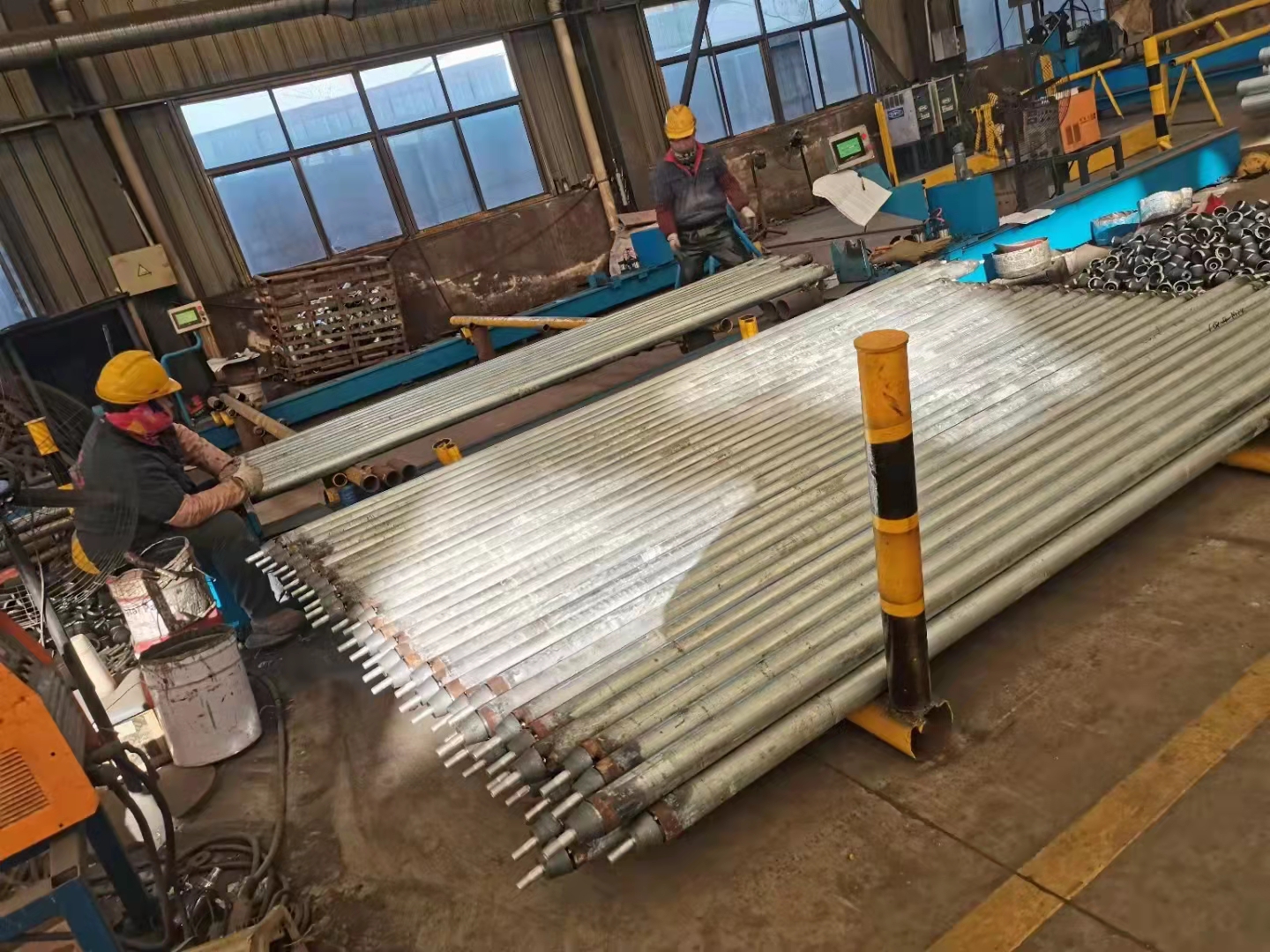

yankan:

A.Masu aikin gine-gine ya kamata su duba zane-zanen gine-gine a hankali, kuma idan an sami matsala, to sai a kai su ga mai fasaha don kauce wa matsala.

magance matsalar cikin lokaci.

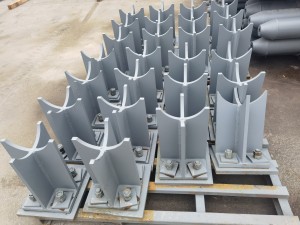

B. Dole ne a lissafta girman manyan nodes ko ƙididdige su.

C. Kayan aikin aunawa da aka yi amfani da su don stakeout, blanking da haɗakarwa da dubawa dole ne su kasance ƙwararrun kayan aikin aunawa waɗanda aka tabbatar da su ta sashen aunawa da gwaji.

D. Layin yankan don blanking dole ne ya zama daidai kuma a sarari, tare da izini don shrinkage walda da yanke aiki.

E. Yanke sassa ya kamata a yanke ta na'ura mai laushi, na'ura mai yankan harshen wuta, haɗaɗɗen nau'i da na'ura mai laushi, na'ura na baka, da dai sauransu, dangane da takamaiman halin da ake ciki, kuma ya kamata a guje wa yankan da hannu kamar yadda zai yiwu.Dubi tebur don halaltacciyar karkatacciyar hanyar yanke hanyoyin daban-daban da yankan saman

F. Nicks na gida tare da zurfin fiye da 1mm akan yankan saman, yanke tare da zurfin fiye da 2mm, da saura

Ya kamata a gyara sauran burbushin da aka goge sannan a goge su.

| Yankan Hanyar da halatta sabawa na yankan surface | |

| Sunan aikin | Hakuri |

| Yankewar atomatik da Semi-atomatik | ± 1.5mm |

| Ƙaƙƙarfan gangaren da ba daidai ba na yankan saman shine | ≤1.5mm |

| Yanke kusurwar bevel | ±3° |

| Yanke baki mara nauyi | ± 2.0mm |

| Yanke hannun | ± 2.0mm |

G. Dole ne a zaɓi nau'in nau'in walda na ɓangaren bisa ga alamar walda da aka yi alama akan zane da siffar tsagi da girman.