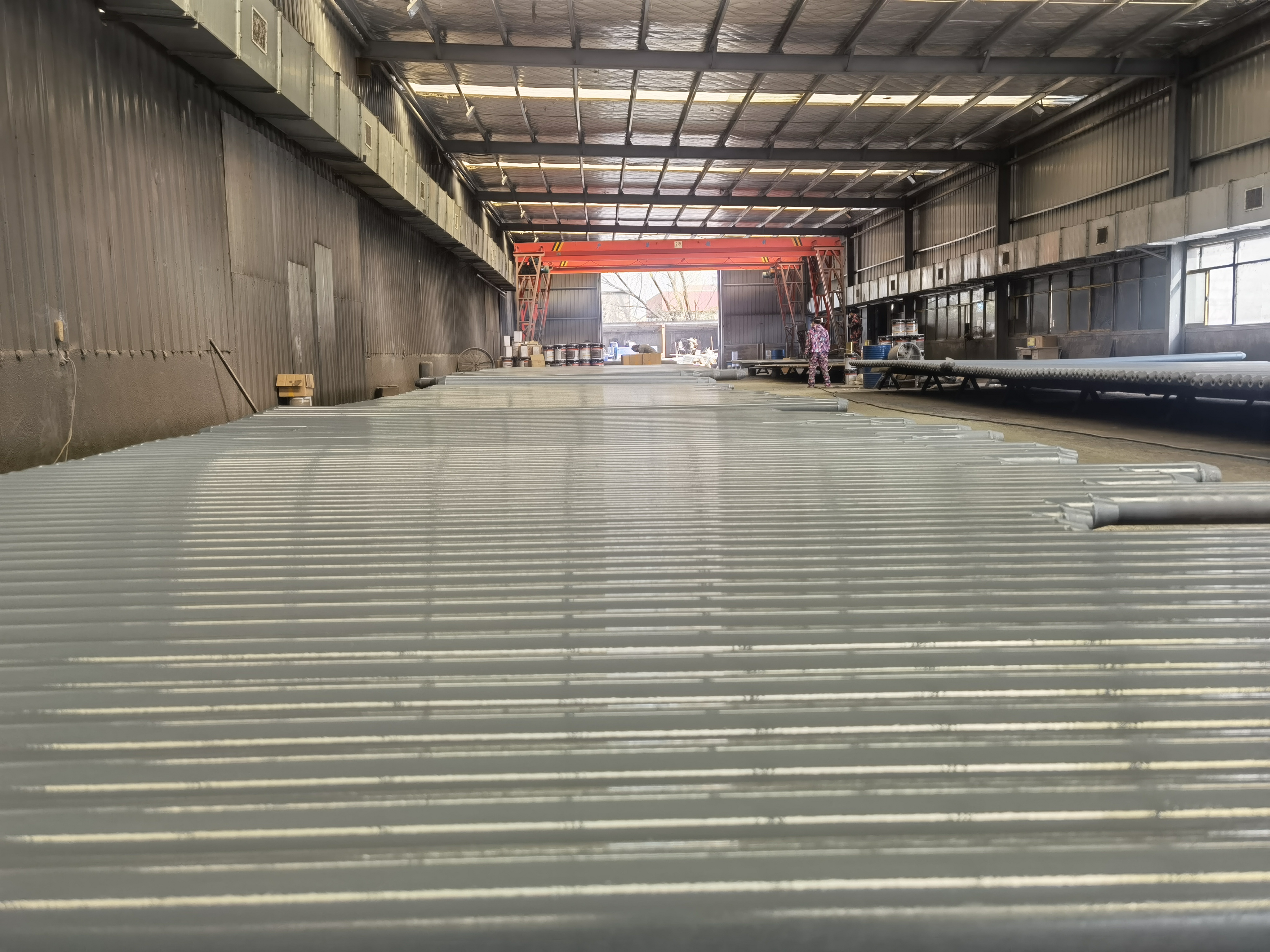

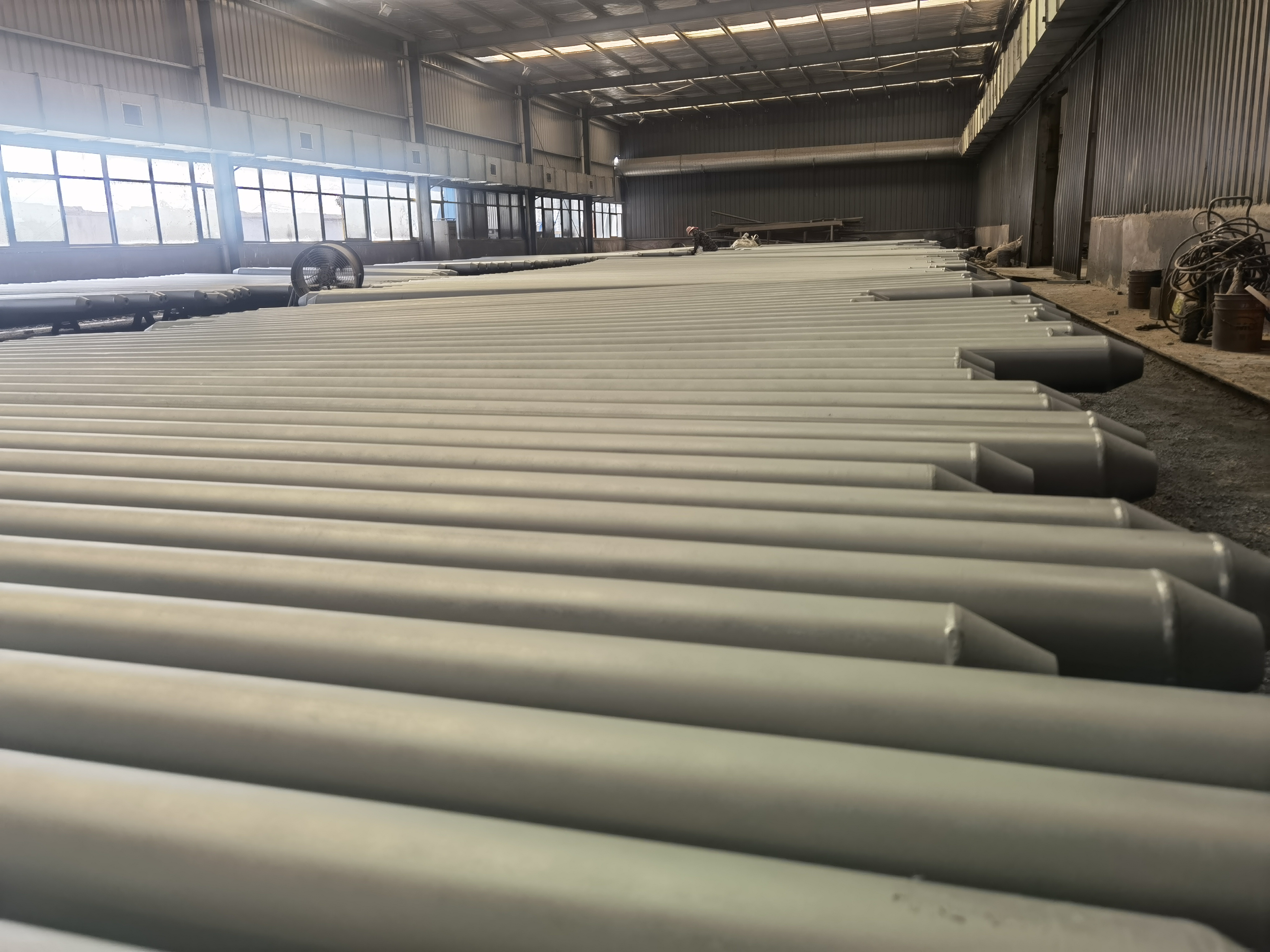

Shot ayukan iska mai ƙarfi da derusting tsari na karfe sarari firam

Harba mai fashewa:

Harba fashewar bom shine a yi amfani da ƙarfin centrifugal na impeller akan na'urar fashewar fashewar lokacin da take juyawa cikin sauri mai girma, kuma tsarin fashewar harbi yana da girma sosai.

Ana harbin saurin layin karfen zuwa saman karfen don a yi maganinsa, yana haifar da busawa da nika, kuma ana cire ma'aunin oxide akan saman karfen.

da tsatsa, kuma suna haifar da wani ƙazanta.Harba fashewa yana da inganci sosai kuma ana iya yin shi a cikin mahalli da aka rufe.

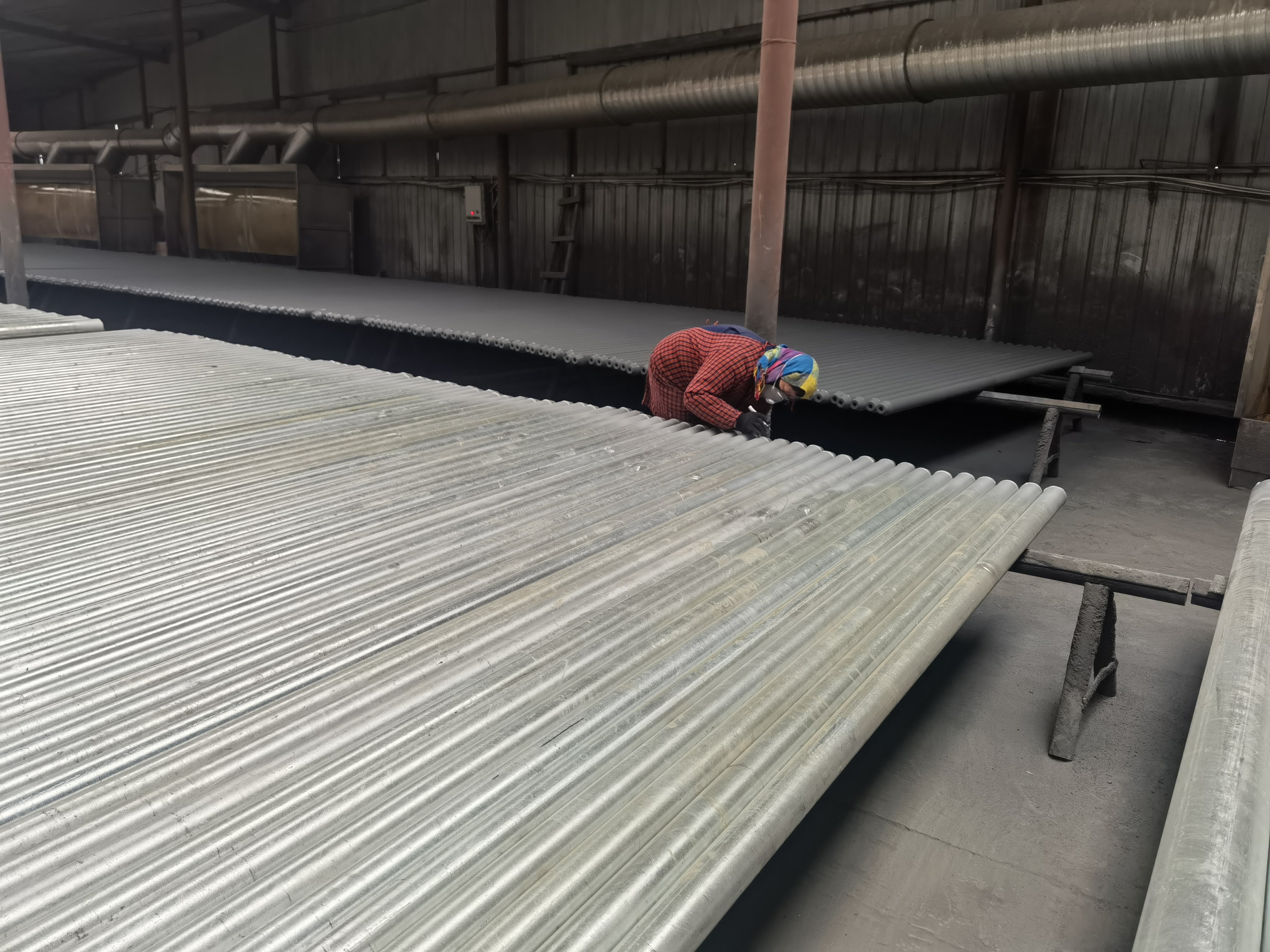

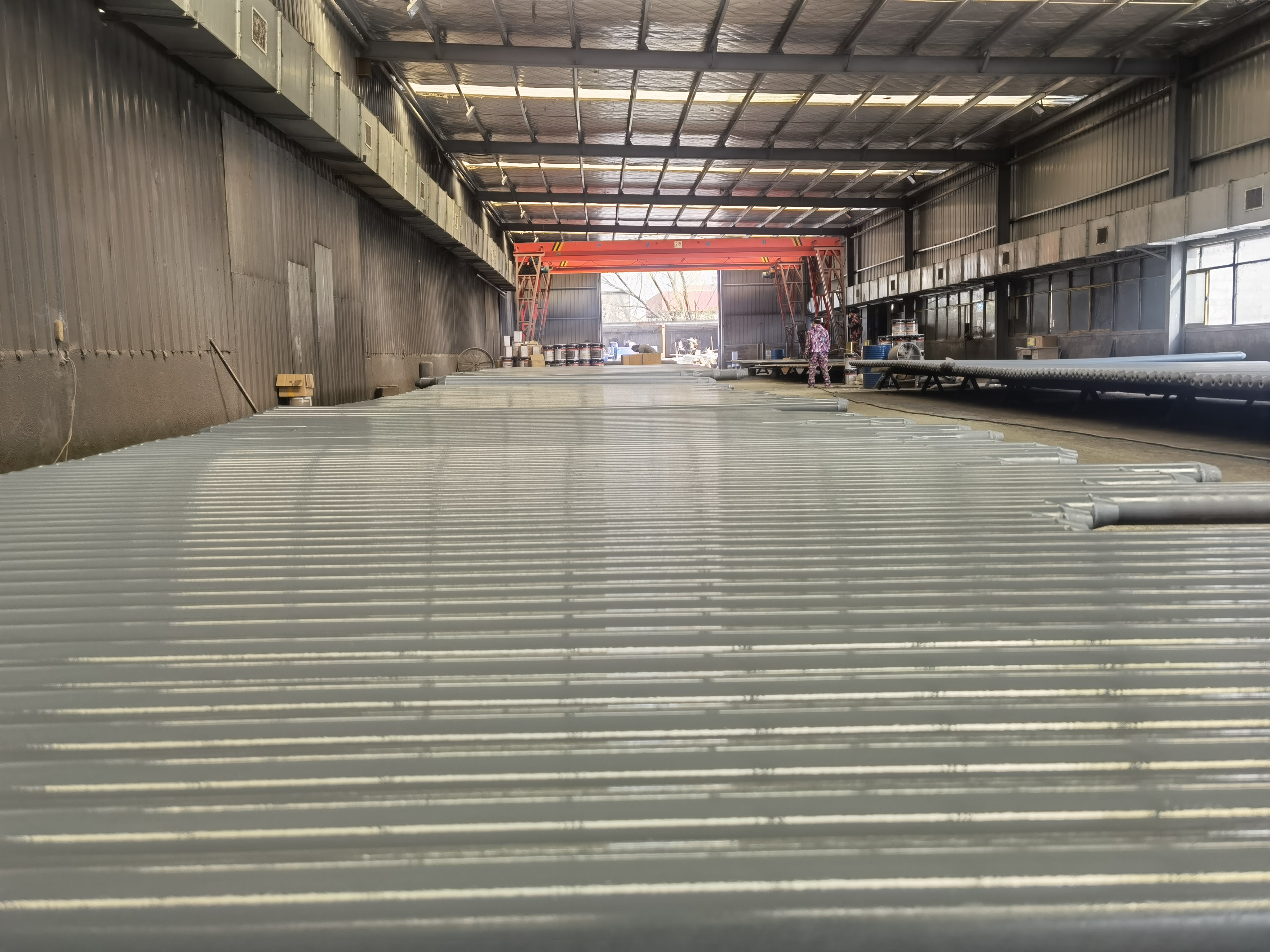

Shot ayukan iska mai ƙarfi da matakin cire tsatsa;

(1) Saurin harbin iska mai sauƙi da cire tsatsa.Ƙarfe ya kamata ya kasance ba tare da man shafawa ko datti ba kuma ba shi da ma'aunin oxide mai ƙarfi, tsatsa da fenti da sauran abubuwan da aka haɗe;

(2) Cikakken harbin iska mai ƙarfi da cire tsatsa.Ƙarfe ya kamata ya kasance ba tare da man shafawa ko datti ba kuma ba shi da ma'aunin oxide mai ƙarfi, tsatsa da fenti da sauran abubuwan da aka haɗe;

(3) Cikakken harbin iska mai ƙarfi da cire tsatsa.Filayen ƙarfe ya kamata ya kasance ba tare da maiko ko datti ba, sikeli, abubuwan da aka makala na ƙarfe kamar tsatsa da fenti, duk wani abin da ya rage ya kamata ya zama ɗan tabo kawai a cikin nau'i na ɗigo ko ɗigo;

(4) Shot ayukan iska mai ƙarfi da cire tsatsa don tsabtace saman karfe.Ƙarfe ya kamata ya kasance ba tare da man shafawa ko datti ba, fata mai oxidation, tsatsa da fenti da sauran abubuwan da aka haɗe, yana nuna alamar ƙarfe na ƙarfe;